Landfill Biodegradable Shrinkwrap products

Say YES to Green!

Biodegradable Shrinkwrap Products

Founded in 2023, bioaqualife® is a pioneering company dedicated to providing innovative sustainable, biodegradable plastic alternatives for use in the marine, construction, agriculture, and packaging industries.

Once placed in landfill conditions, all bioaqualife products attract microbes, and as they are digested, the molecular structure of the material breaks down into soil and natural gases and leaves no microplastics behind.

The bioaqualife® team is committed to environmental stewardship and creating eco-friendly performance products that will revolutionize the single-use plastic industry.

Marine

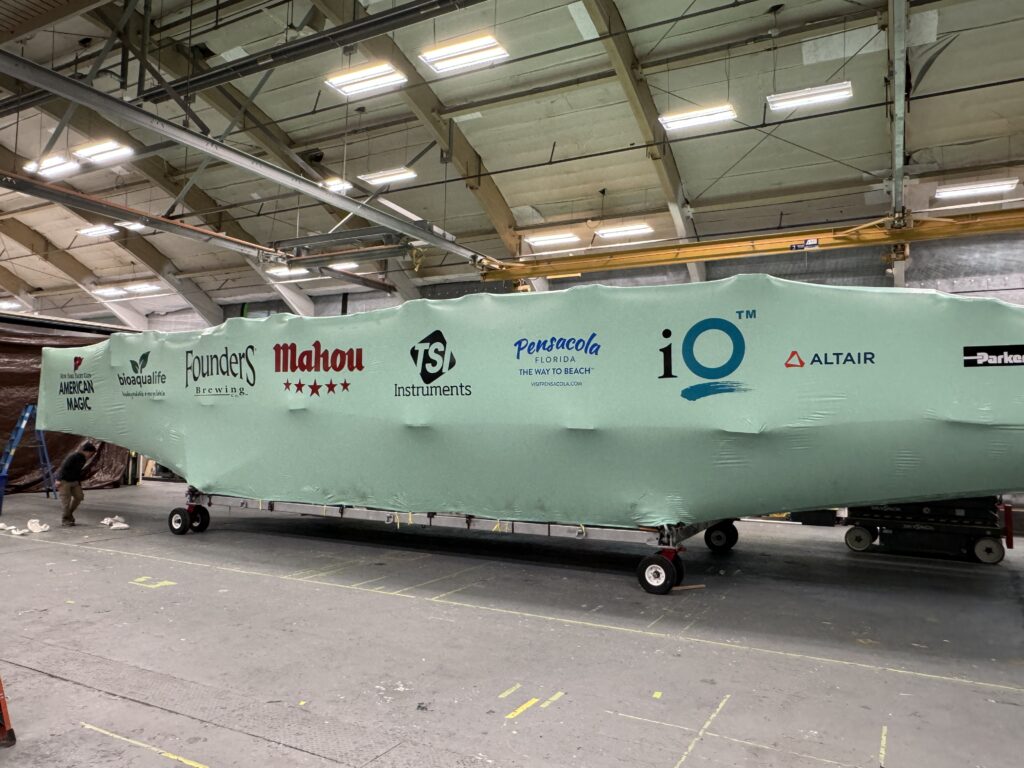

Our unique bioWrap® protects marine vessels that need protection from the elements in the off season and during transportation. The bioWrap® shrinkwrap is strong, durable, biodegradable, and recyclable.

In the US alone, more than 92 million pounds of shrinkwrap are used for boats, and the majority ends up in community landfills. Since bioWrap® degrades using microbial consumption, it minimizes environmental contamination.

Construction

Builders and other industries rely on our durable, heavy-duty

but lightweight bioWrap® is used in construction and

recreational projects.

Applications include enclosures, vapor barriers, temporary liners and covers, containment, and even for recreational events.

Our bioWrap® is manufactured in the U.S. to meet the needs of any of your applications.

bioaqualife® bioWrap® statistics:

Why should you prefer our bioWrap® to the majority of available options on the market?

Our bioWrap® can be collected, processed, and reused to create new items or products. This process helps reduce waste and conserve resources by turning used materials into new raw materials, thereby minimizing the need for virgin resources.

Our bioWrap® has been tested and verified by a laboratory to decompose naturally through biological processes. This means that it can break down into natural substances like water, carbon dioxide, and biomass in a specific period under certain environmental conditions.

A material that meets ASTM E84 Class A fire retardant rating is considered to be highly effective in resisting fire and minimizing smoke production.

Our shrink wrap is designed to provide a quick and efficient way to secure items, making it ideal for bundling products or for applications where fast packaging is essential.

Please select the dimension of the shrink wrap you need for your project from variety of sizes available.

Supporting local manufacturing not only boosts the economy but also fosters job creation and community development. By choosing products made in the USA, consumers contribute to a legacy of excellence!

bioaqualife – Helping The Planet

By choosing bioaqualife, businesses and consumers alike can minimize their carbon footprint and support eco-friendly practices.

In The US Just For Boat Shrinkwrap

500 million tons of plastic are produced annually worldwide.

A staggering amount ends up in community landfills.

Do your part by choosing bioaqualife products that biodegrade without creating microplastics.

Nano and Micro Particles in 1 Water Bottle

Don’t confuse degradation into smaller nanoparticles with TRUE biodegradation. Our products degrade by microbial action, creating only good bacterial waste byproducts.

No sunlight or oxygen is needed!

Take a peek at short presentation

Read Our Story About Helping the Planet Earth

Choose biodegradable bioWrap®!

Embracing a Sustainable Future with bioWrap®

Creating a digestible feast for landfill bacteria

At bioaqualife, we are pioneering a revolutionary solution that combines environmental sustainability with uncompromising performance. Our proprietary bioWrap® products are a game-changer in the realm of eco-friendly alternatives to traditional plastics.

Crafted with a unique formulation that includes a proprietary ingredient, bioaqualife’s bioWrap® products boast exceptional biodegradability. Remarkably, 3rd party testing is showing our bioWrap® biodegrade at a rate of 20.8% within just 183 days in landfills, ensuring a cleaner and greener future for generations to come. (ASTM D5511)

But our commitment to sustainability doesn’t stop there. bioWrap® products are fully recyclable. Our films meet the stringent ASTM E84 Class A ratings for optimal safety and performance. This comprehensive approach to environmental stewardship sets bioaqualife apart as a leader in the pursuit of a sustainable tomorrow.

Our mission is to replace harmful plastics with non-toxic, biodegradable products. By embracing bioWrap®, you are actively contributing to a cleaner planet, one community at a time. bioaqualife is dedicated to delivering innovative solutions that pave the way for a greener future.